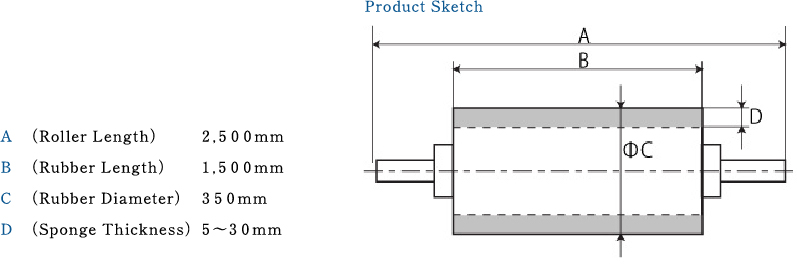

Sponge roller

It is great rubber roller being produced for more than 40 years and being used for gluing or coating Plywood, Flooring , Exterior Wall and so on in the industry-leading manufacturers in Japan.

It is great rubber roller being produced for more than 40 years and being used for gluing or coating Plywood, Flooring , Exterior Wall and so on in the industry-leading manufacturers in Japan.